India’s copper story critically dependent on the quality of scrap processing

The International Copper Association India recently launched the Copper Stock and Flow Model that emphasizes the pivotal role of quality of scrap processing as 70% of copper is used for electrical applications, urging immediate action for improved responsible recycling practices. The model highlights the gap between global practises of refining scrap copper as compared to almost 100% remelting of scrap in India.

As per the findings, almost 38% of India’s copper demand is met through scrap copper. In the fiscal year 2021, India generated almost 350 KT (kilo tonne) of end-of-life and process copper scrap, supplemented by the import of an additional 80 KT of copper scrap.

Most of the remelted copper is used in form for rods and billets concentrated in the electrical and electronics segment. The recycling process must focus on refining high-grade scrap and smelting & refining low-grade scrap to eliminate impurities. However, the share of secondary smelting and refining of scrap in India remains at a mere 1%, significantly trailing behind leading economies such as China (32%), the EU (30%) and Japan (16%). Presently, India primarily relies on direct melting of scrap, resulting in variable copper purity due to the use of diverse scrap types. Traditional methods are employed to reduce impurities, producing copper rods or billets which are non-compliant to the national standard. The Indian Copper Stock and Flow model indicated that a significant portion of direct melt copper scrap goes into semis production. This percentage is notably higher compared to key global economies, with Japan, the EU or China.

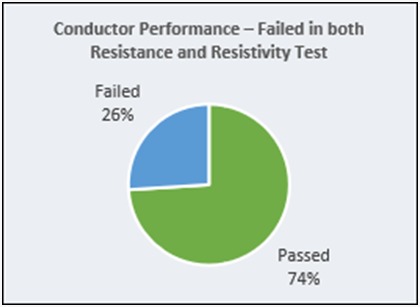

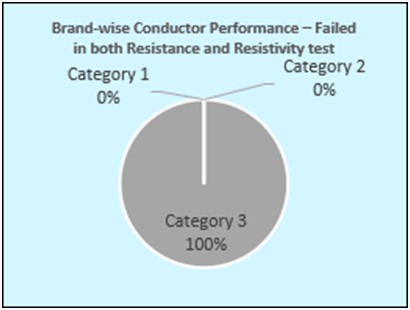

The direct remelting of copper in semis fabrication raises quality concerns, especially regarding tramp elements (elements that cannot be removed easily by direct remelting process) in conductor applications. ETP grade copper, with a required purity of 99.9% or more as per IS12444 standards, is crucial for all electrical installations.